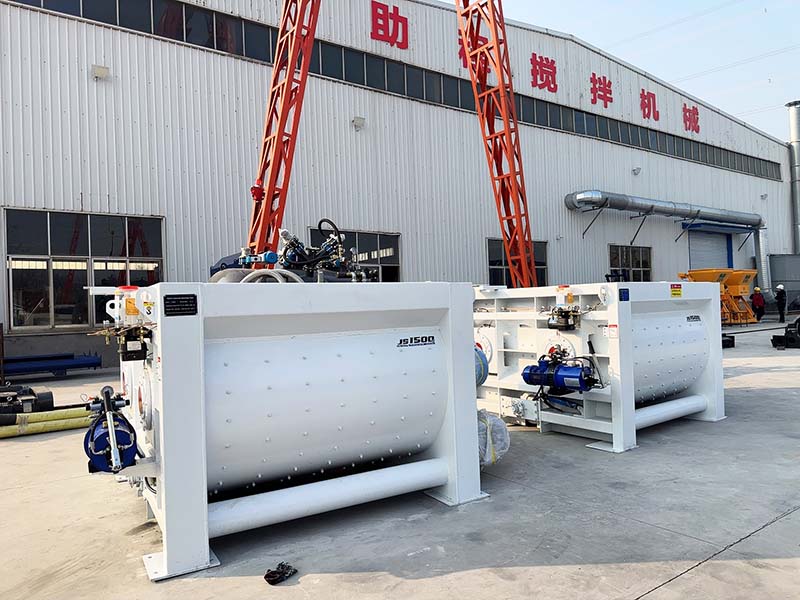

90m³/h Concrete Batching Plant to Tajikistan

We are thrilled to announce the successful dispatch of our 90m³/h stationary concrete batching plant to a key client in Tajikistan. This shipment marks a significant step in our company's growing presence in Central Asia and underscores our commitment to supporting robust infrastructure development in the region. This particular model, a cornerstone of our product line, is engineered for projects demanding high-volume, consistent, and reliable concrete production. It is ideally suited for large-scale construction initiatives such as highways, bridges, dams, and commercial hubs—precisely the type of development actively underway in Tajikistan. Product Advantages: Engineered for Performance and Partnership Our 90m³/h...