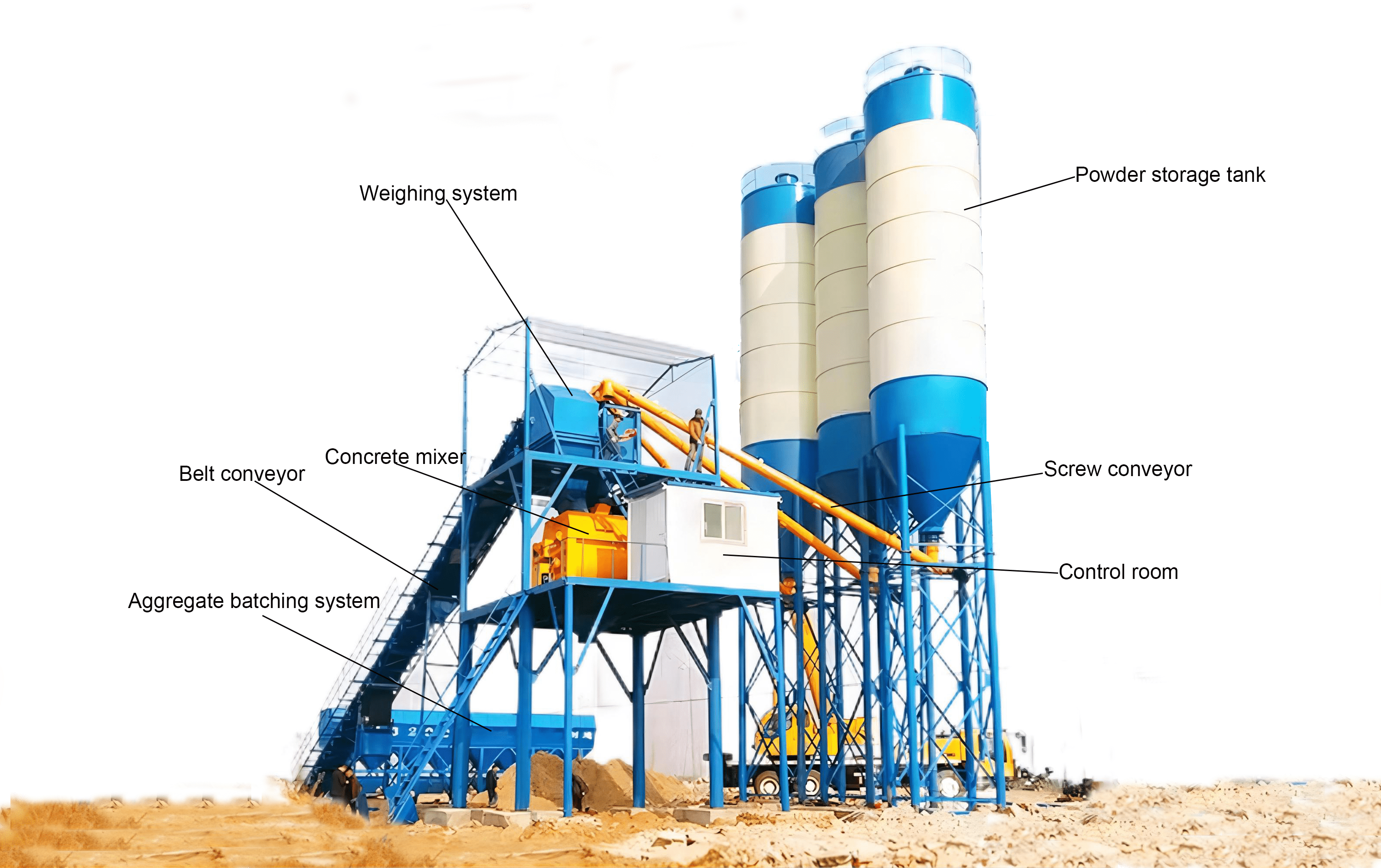

HZS120 Concrete Batching Plant

Introduction

HZS120 belt concrete mixing plant adopts a JS2000 double horizontal shaft concrete mixer, batching machine adopts a PLD3200 batching machine, the theoretical output is 120 cubic meters per hour.

Main Details

Mixing system

1.Perfect multi-sealing system to avoid leakage and protect shaft ends.

2.Equipped with changeable wear-resistance blade and liner plates, lifetime is over 60,000 times.

3.Equipped with auto lubrication pump, once fill for 5-7 days running.

4.Advanced motor and reducer driven system to keep stable performance.

Weighing System

1.Powder and water or additives are measured independently, ensuring rapid action and high accurate measurement.

2.High accuracy sensor ensures the error no more than 1%.

Aggregate Batching Cystem

1.Sand storage bin is with large vibrator, guarantee smooth and fast discharge.

2.Accumulative weighing system and separate weighing system are available choice.

3.High accuracy sensor ensures the error no more than 2%.

Aggregate Conveying System

1.Inclined angle up to 32 degree, stand small area.

2.Equipped with recycled belt conveyor to reuse the leakage material.

3.Vibrating Return cover to avoid sticks.

4.Equipped with maintenance aisle. Easy for maintenance and clean.

5.Fully rain cover to reduce the dust emission and protect the belt if customers need.

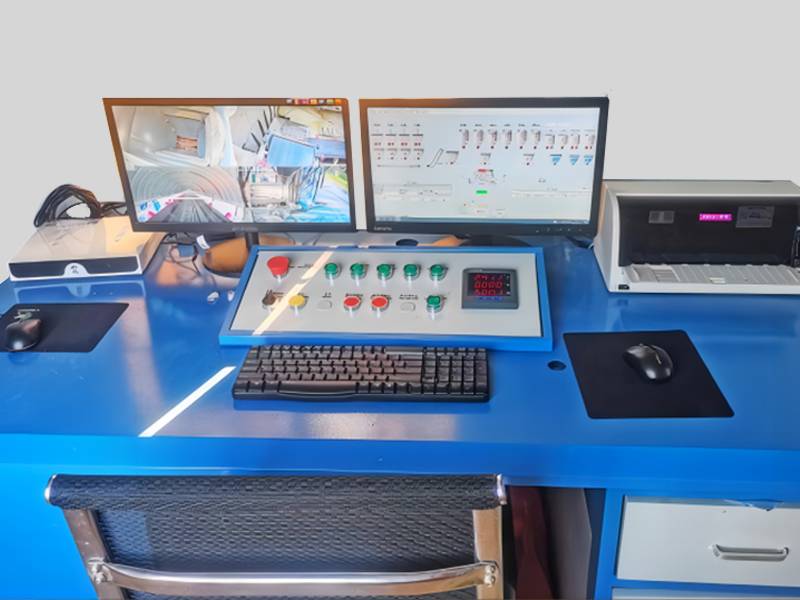

Control System

1.Automatic or manual can be adjusted flexibly smoothly.

2.All wires & cables are coded, easy to track and maintenance.

3.Intelligent management system for task tracking, printing, etc.

4.Computer+ PLC control system to ensure simple and stable operation, HD display can show clearly about the operation of each part.

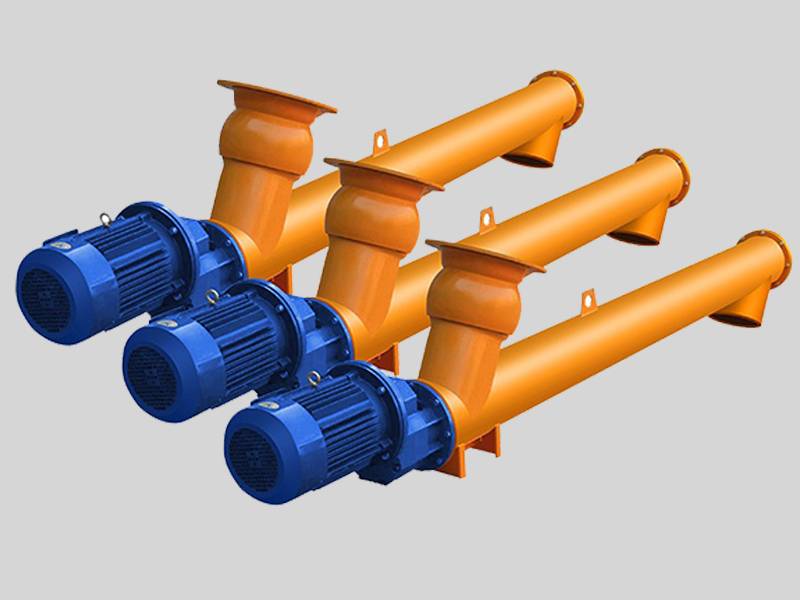

Cement Screw Conveyor

1.High revolving speed, large conveying capacity, high precision and nice conveying condition.

2.Easy assembly, easy connection, reliable sealing and wide application.

3.Suitable for conveying a variety of powder, granular, small bulk materials.

4.Diameter as φ219mm/φ273mm/φ325mm, lengths as 6m, 8m or 10m, all can be customized.

Cement Silo

1.Vertical cement silo and horizontal cement silo are available for selection.

2.Capacity range from 50T to 300T. Accessories are including air-break device, gate valve, relief valve, level indicator, dust collector, etc.

3.High-quality steel, good sealing, stable support and long service life.

Advantages

Services

Pre-sale Services

1.Quick response.

2.Provide detailed quotation.

3.Provide scheme design and site planning.

4.Accept customer's visit.

On-sale Services

1.If necessary, send technicians to the site for installation and commissioning.

2.Provide complete technical information.

3.Free training of operators.

After-sale Services

1.One year warranty for mixing equipment, two years warranty for core electrical appliances, free accessories for quality problems during the warranty period, except for wearing parts.

2.Make regular remote visits.

3.Lifelong after-sales technical support service.

Customer visits

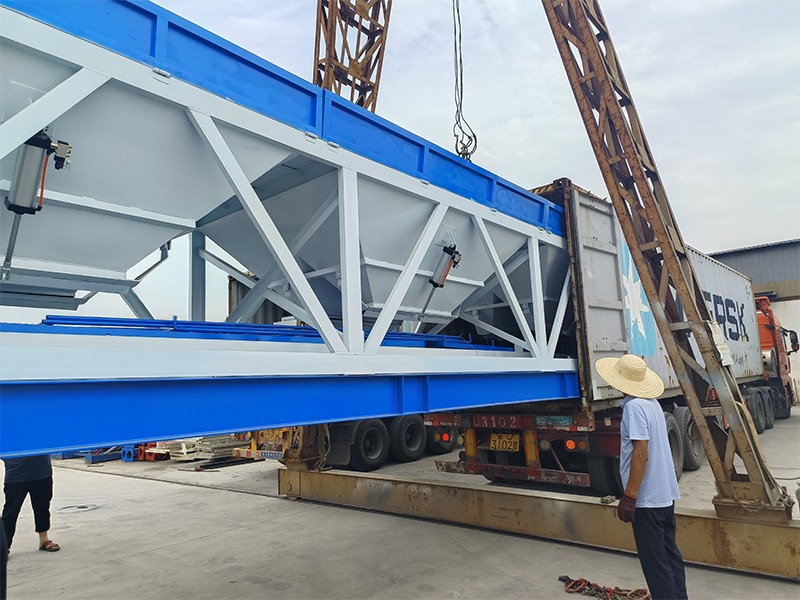

Delivery

Application