Introduction

JS500 concrete mixer is a double-horizontal-shaft forced mixer. Each drum can mix 500L of concrete (referring to the volume of compacted concrete), and can produce 30 cubic meters per hour.

Main Details

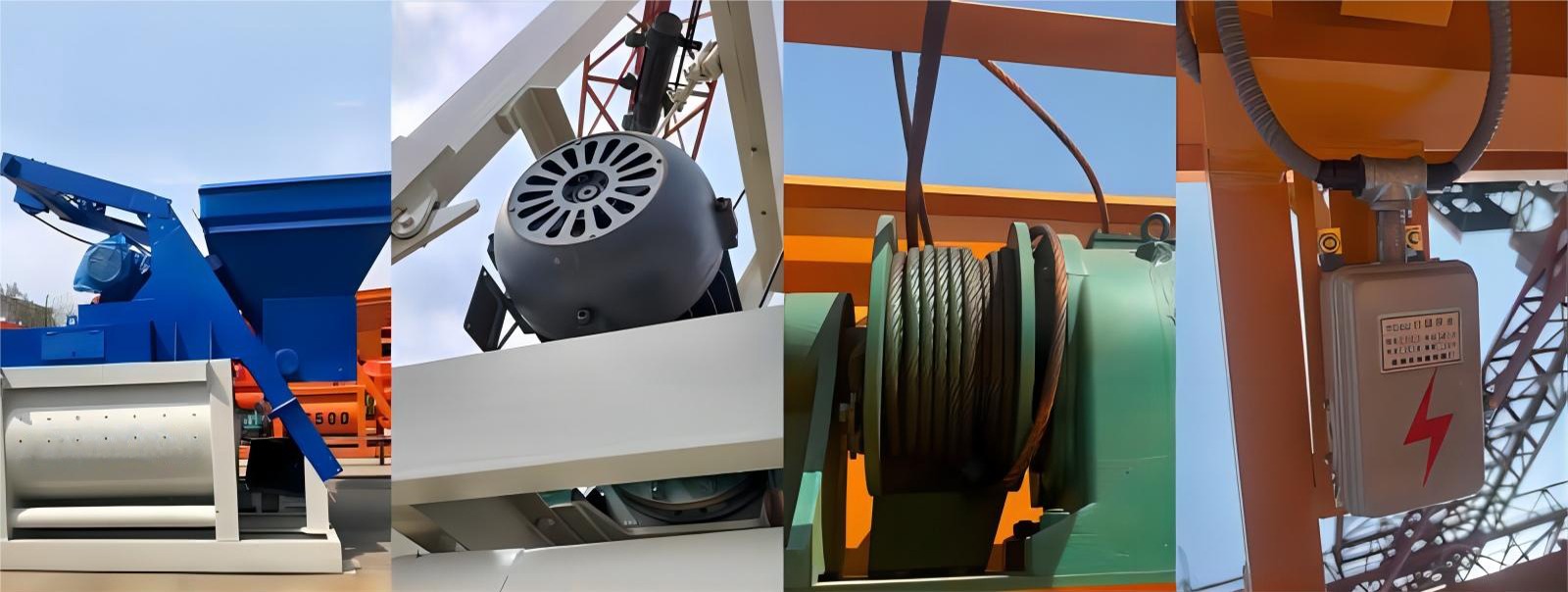

Mixing System

1.The mixing system is composed of motors, belt pulleys, reducers, open gears, mixer drums, oil supply device and other mechanisms.

2.High-temperature resistant all-copper motor works for a long time without burning the machine.

3.Equipped with high performance cycloidal pin reducers, bring the whole machine stable running and low noise.

4.The mixing shaft, mixing arm, mixing blade and liner are made of thickened and wear-resistant high manganese-chromium alloy, which make the mixing evenly and stably.

5.Multiple shaft end sealing protection technology, high production efficiency and long service life without slurry leakage.

Feeding System

1.The upper part of the feeding frame can be folded, which is convenient to reduce the transportation height during transportation.

2.The ascending limiter (limit switch) prevents the hopper from rushing to the top, which plays a role in limiting and safety protection.

3.Wire rope pulley, precision machining, safe and reliable. Wire-contact steel wire rope is adopted, which has small gap contact stress, small wear, large bearing capacity and long service life.

Discharging System

1.The discharging system is composed of discharging door, air cylinder or hydraulic cylinder, gas pump, reversing valve and gas distribution valve. There are three discharge way: hydraulic control, pneumatic control and manual control.

2.The discharge door is installed at the bottom of the mixer, and pneumatic discharge is through the air cylinder or hydraulic cylinder.

3.Manual operation, using manual control lever. It is used for emergency unloading in case of temporary power failure, or when pneumatic or hydraulic cylinder fails.

Water Supply System

1.The water supply system consists of water pump, throttle valve, cleaning device and spraying device.

2.With the 360-degree spraying device, the spraying speed of water flow is high, the coverage of water flow is large, the spraying efficiency is improved, the water consumption is greatly reduced, and the production cost is reduced.

3.Throttle valve can adjust the water-saving flow and limit the speed of fluid passing through the valve, so as to control the flow rate and pressure.

Electrical System

1.The electric control system is equipped with air switch, fuse and thermal relay, which has the functions of short circuit protection and overload protection.

2.All control buttons, air switch handles and indicator lights are evenly arranged on the distribution box door, and a door lock is provided. A small protective door is arranged outside the button.

3.The electrical components in the distribution box are mounted on an insulating board, which is safe and reliable and convenient to operate and maintain.

Advantages

Service

Pre-sale Services

- Quick response.

- Provide detailed quotation.

- Provide scheme design and site planning.

- Accept customer's visit.

On-sale Services

1. If necessary, send technicians to the site for installation and commissioning.

2. Provide complete technical information.

3. Free training of operators.

After-sale Services

- One year warranty for mixing equipment, two years warranty for core electrical appliances, free accessories for quality problems during the warranty period, except for wearing parts.

- Make regular remote visits.

- Lifelong after-sales technical support service.

Customer Visits

Delivery

Application