Introduction

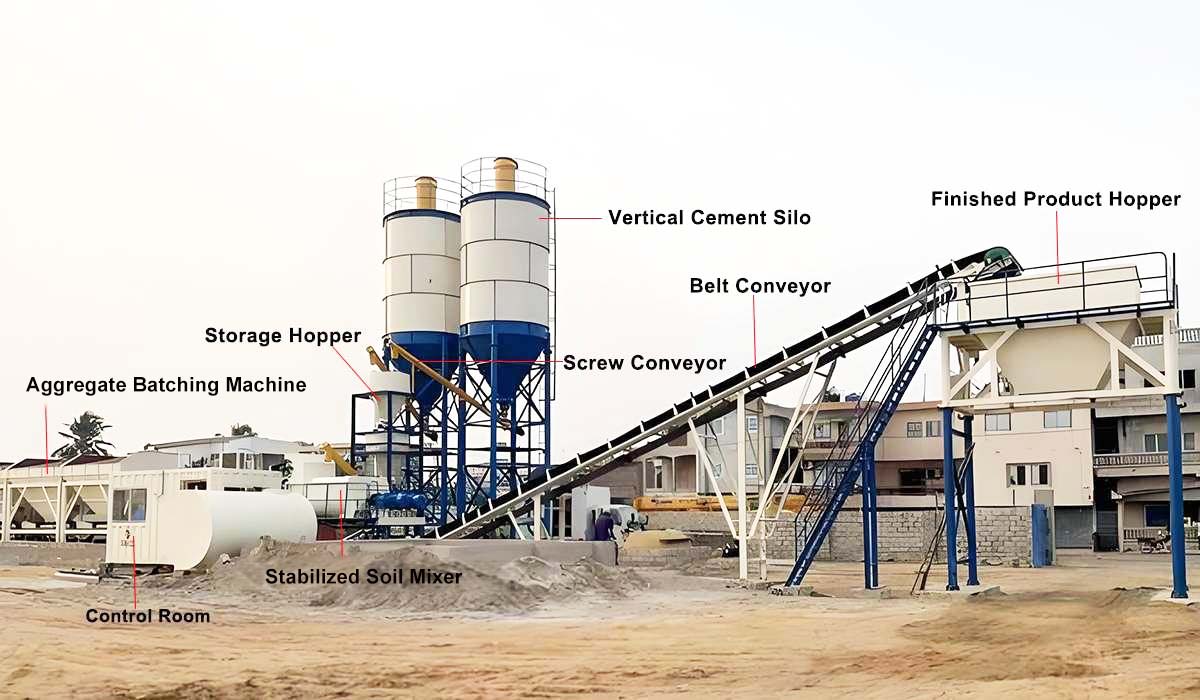

Stationary stabilized soil mixing plant is suitable for large scale continuous operation of the stable layer of highway construction. The aggregate, power and water adopt frequency conversion to control the rate of flow, which achieves high measuring accuracy and stability. The quantity of aggregate storage bins can be changed from four to six according to the needs of the project.

Main Details

Mixing System

- The main engine adopts bilateral four-hole maintenance position, so it is convenient and quick to clean the machine and replace the blades during production.

- Double-bearing liner-less cylinder body reduces blade wear, and eliminates failures such as material jam, hard scratch, etc.

- Wear-resistant round steel mixing knife wall and blade, non-stick material, easy to clean.

Batching System

- The batching hopper has a large volume and a wide feeding hole, which can realize bilateral feeding.

- The whole frame is made of H steel, which has strong compression resistance and no deformation.

- Built-in vibrator is standard, which solves the problems of blocked silo and poor blanking.

- Sensor weighing, measuring materials separately, improving batching accuracy.

Conveying System

- It is divided into two parts: the screw conveyor and the belt conveyor.

- The spiral conveyor adopts automatic welding technology and baking paint treatment technology, thickening spiral blades, mature technology and stable quality.

- Belt conveyor adopts skirt conveyor belt, which does not spill or leak materials in the middle of production process, reducing production cost and waste of raw materials.

Finished Product Hopper

- The whole series is equipped with waiting bins, which can change cars without stopping in the production process, which is simple to operate and reduces the waste of raw materials.

- Fully automatic control of door opening and closing saves manual operation cost.

Control System

- The working panel has clear flow, simple operation, and the system intelligently detects and displays each measurement and weighing.

- As a state, it has the function of self-vibration due to lack of materials and alarm for over-shortage.

- At the same time, in special circumstances, it can also be operated manually, and the whole process can be completed by only one person.

Cement Silo

- Cement silo can be equipped with flaky cement silo, vertical cement silo and horizontal cement silo.

- The cement silo is equipped with a material level device and a dust removal system, and the cone of the silo is equipped with an arch breaking device.

- Powder conveying is fully sealed, pollution-free and waste-free.

Advantages

Service

Pre-sale Services

- Quick response.

- Provide detailed quotation.

- Provide scheme design and site planning.

- Accept customer's visit.

On-sale Services

1. If necessary, send technicians to the site for installation and commissioning.

2. Provide complete technical information.

3. Free training of operators.

After-sale Services

- One year warranty for mixing equipment, two years warranty for core electrical appliances, free accessories for quality problems during the warranty period, except for wearing parts.

- Make regular remote visits.

- Lifelong after-sales technical support service.

Customer Visits

Delivery

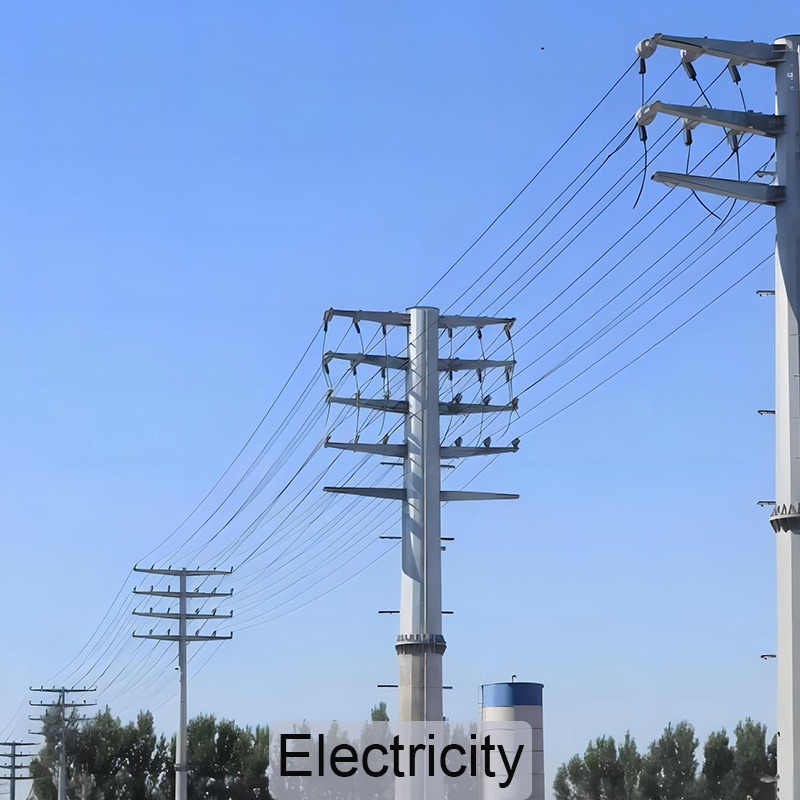

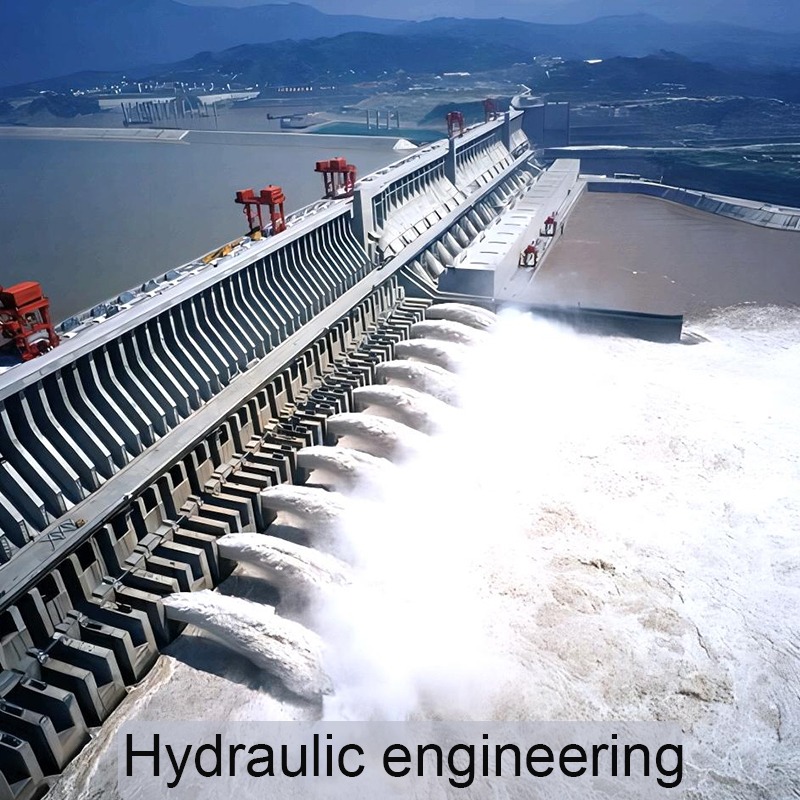

Application