Introduction

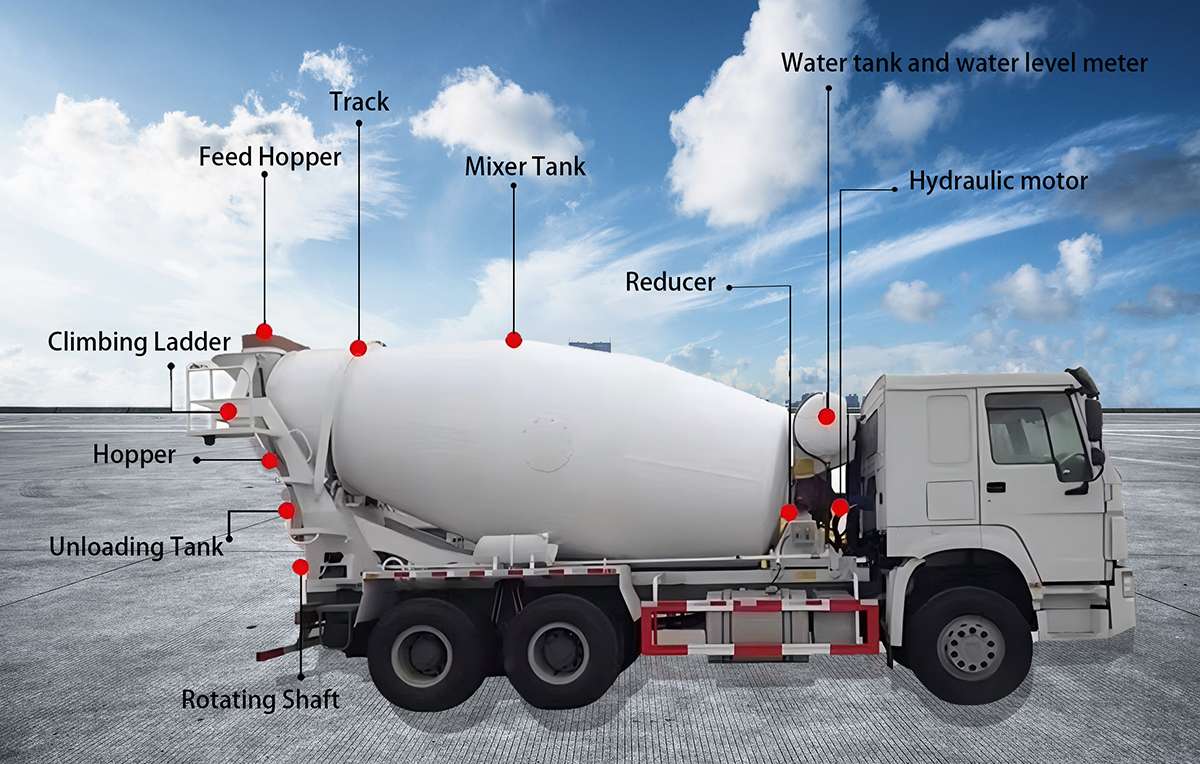

The concrete mixer trucks are made to mix concrete and transport concrete to the construction site. During transportation, the mixing drum will always rotate to ensure that the concrete carried will not solidify. It consists of chassis, concrete tank, feeding and discharging devices, hydraulic transmission system and cooling system. The volume of the mixer truck is usually between 3 and 16 cubic meters.

Main Details

Hydraulic Motor

Imported tank rotating motor has large torque and is not easy to leak oil.

Reducer

Brand reducer, effectively reduce the speed.

Slewing Support

Closed screw, to avoid sand and dust and other debris from entering.

Heat-removal System

Prevent the hydraulic oil tank from overheating.

Pressure Water Tank

Equipped with pressure water tank, it can maintain constant pressure, stabilize pressure, replenish water and overflow, and clean the tank and body.

Tail Discharge Chute

The tail discharge chute is designed to be spliced and folded, with large-diameter notch, which makes the discharge convenient and fast.

Thickened Tank

High strength tank, low wear, easy maintenance, durable and not easy to rust.

Driving Cab

1. Open and close the door at 90 degrees, which is convenient for entry and exit.

2. The whole vehicle is equipped with a camera to monitor and master the driving condition in real time.

Advantages

Service

Pre-sale Services

- Quick response.

- Provide detailed quotation.

- Provide scheme design and site planning.

- Accept customer's visit.

On-sale Services

1. If necessary, send technicians to the site for installation and commissioning.

2. Provide complete technical information.

3. Free training of operators.

After-sale Services

- One year warranty for mixing equipment, two years warranty for core electrical appliances, free accessories for quality problems during the warranty period, except for wearing parts.

- Make regular remote visits.

- Lifelong after-sales technical support service.

Customer Visits

Delivery

Application