What Do You Know the Mobile Self-loading Concrete Mixer Truck?

Self-loading concrete mixer is a special type of concrete mixer truck, which can produce concrete on site, automatically load it into the mixing tank, and then transport it to the construction site. This equipment combines the functions of loading, mixing and transportation, which greatly improves the construction efficiency.

I. Introduction of mobile self loading concrete mixer truck

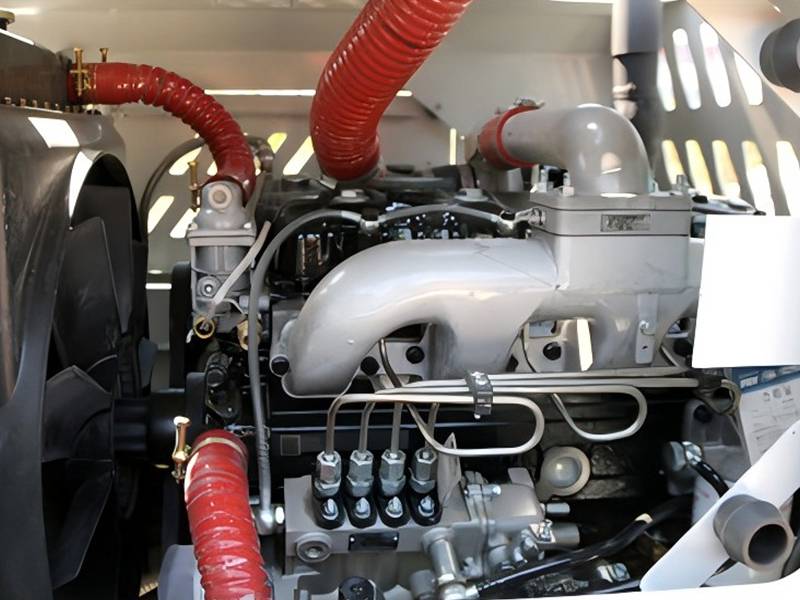

The main components of self-loading mixer trucks include body, mixing device, transmission device and hydraulic system. Its working principle is that before transportation, the prepared cement, aggregate, sand and additives are mixed together and placed in a mixing tank, which is continuously stirred during transportation, and the mixed materials are sent from the mixing tank to the screw conveyor through the conveyor, and then sent to the discharge port through the screw conveyor, and finally a certain proportion of concrete is produced and poured on site.

II. Principle of mobile self loading concrete mixer truck

1. Materials enter the machine body from the feed hopper and are pushed into the mixing drum by the screw propeller.

2. The materials in the mixing drum are fully dispersed and crushed under the action of centrifugal force and shear force generated by the rotating shaft.

3. When the material is crushed to a certain fineness, it is discharged from the discharge hopper.

4. The discharged materials are pushed back to the feed hopper through the screw propeller to re-add raw materials for cyclic operation.

III. Working principle of self-loading concrete mixing truck

The motor drives the spindle to rotate through the reducer and drives the mixing cylinder to rotate; The mixing cylinder body is connected with a lining plate fixed in the mixing cylinder body to form a sealed chamber, and objects to be mixed are put into the sealed chamber for mixing or crushing; After being evenly stirred, it can be unloaded from the slag outlet to complete the operation. The bearing seat and bearing cover with fully enclosed structure and special wear-resistant materials ensure the reliability and service life of the equipment.

The working principle of automatic feeding concrete mixer truck is mainly divided into the following steps:

1. Feeding system: The automatic self feeding cement mixer truck is equipped with an advanced feeding system, which can automatically load raw materials into the mixer from its own hopper. The feeding system usually consists of a screw conveyor for conveying materials and an electric control system for controlling the operation of the conveyor. The operator only needs to put the raw materials into the hopper, and can start the feeding system by pressing the button or using the remote controller to realize automatic charging.

2. Stirring system: The stirring system of the automatic self loader mixer truck consists of a stirring paddle, a driving device and a control system. The mixing paddle is driven by the driving device, which fully mixes the raw materials in the mixing truck to ensure the quality and uniformity of concrete. The control system of the mixing system can adjust the mixing time and speed as needed to meet the requirements of different types of concrete.

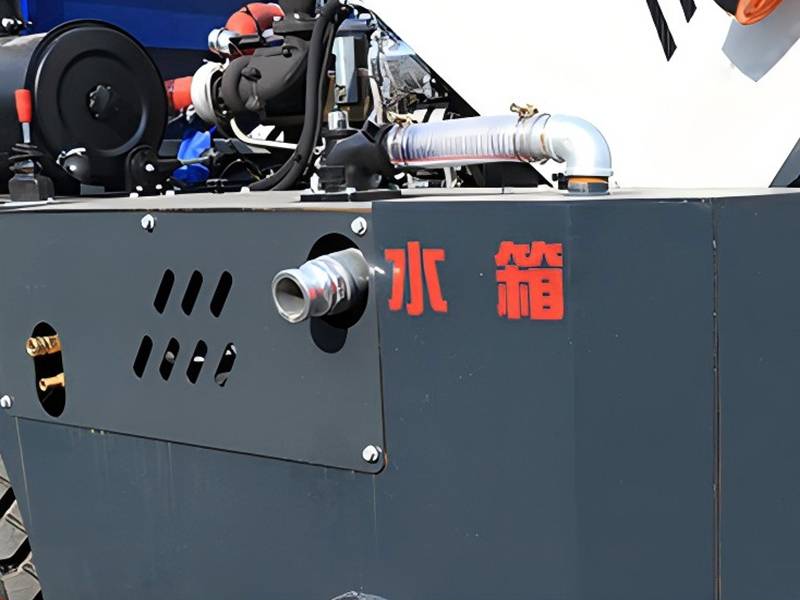

3. Transportation system: The automatic mobile self feeding cement mixer adopts an efficient transportation system, which can transport the mixed concrete to the target site quickly and smoothly. The transportation system usually consists of a hydraulic pump and a conveying pipe. The concrete is sent to the conveying pipe by the hydraulic pump, and then the concrete is conveyed to the target site by the conveying pipe. The transportation system can also adjust the length and angle of the conveying pipe as needed to meet the requirements of different construction sites.

IV. Advantages of self loading mobile concrete truck mixer

Compared with the traditional concrete mixer truck, the automatic feeding concrete mixing truck has the following advantages:

1. Efficient and energy-saving: The automatic feeding cement mixer truck adopts an advanced automatic feeding system, which can quickly and accurately load raw materials into the mixer, saving manpower and time costs. At the same time, the automatic feeding mixer also adopts advanced mixing and transportation system, which can efficiently mix and transport concrete and improve the construction efficiency. In addition, the automatic feeding mixer also has an advanced energy management system, which can realize the best use of energy and reduce the waste of energy.

2. Simple operation: The operation of the auto-loading concrete mixer truck is very simple, and the feeding and mixing work can be completed only by pressing the button or using the remote control. Operators don't need to enter the mixer to load in person, which greatly reduces the work risk and labor intensity. In addition, the control system of automatic feeding mixer usually adopts man-machine interface, and the status and operation guidance of each system are displayed on the display, which makes the operation more intuitive and simple.

3. Controllable quality: The automatic loading mobile concrete mixer adopts an advanced mixing system, which can accurately control the mixing time and speed of the concrete to ensure the quality and uniformity of concrete. In addition, the automatic feeding mixer can also adjust the mixing time and speed as needed to meet the requirements of different types of concrete.

VI. The Application Scenarios of Self-loading Concrete Mixer

Automatic self charging concrete mixer truck has a wide range of application scenarios in building construction, including but not limited to the following aspects:

1. Building construction: The self loader concrete mixer can be used for concrete mixing and transportation in building construction. It can quickly and efficiently load raw materials into the mixer, and transport the mixed concrete to the required place to meet the requirements of different construction tasks.

2. Road and bridge construction: The automatic mobile self loading concrete mixer also has an important application in the construction of roads and bridges. It can automatically load raw materials into the mixer, and then transport the mixed concrete to the construction site of roads and bridges quickly and smoothly, so as to improve work efficiency and quality.

3. Foundation construction: The auto mobile self feeding cement concrete mixing truck can be used for concrete mixing and transportation in foundation construction. It can automatically load raw materials into the mixer, and then transport the mixed concrete to the construction site of foundation and floor, providing fast and efficient service for foundation construction.

VII. Operating steps of self-loading concrete mixer truck

1. Choose a flat and solid parking position for loading and unloading operations.

2. Load the raw materials into the hopper to avoid overloading. 3. Drive safely to the destination and avoid sudden braking and sharp turns.

4. After arriving at the destination, choose the appropriate unloading position and discharge evenly.

5. After discharging, flush the flat mouth and carriage of the mixer with clear water to prevent the concrete residue from solidifying.

6. Carry out regular maintenance according to the manufacturer's requirements and maintenance plan.

The automatic ready dry wet mix 1.5m3 2.0m3 2.5m3 3.5m3 4m3 self loading concrete mixer truck is an advanced concrete mixing and transportation equipment. It can efficiently load raw materials into the mixer through the automatic feeding system, thus improving the construction efficiency and reducing the labor intensity of workers. Automatic feeding cement mixing truck has the advantages of high efficiency, energy saving, simple operation and controllable quality, and has a wide range of application scenarios in building construction. With the continuous development of science and technology, it is believed that the automatic feeding mixer will be further improved and perfected to provide more efficient and better service for building construction.