Introduction

Asphalt concrete mixing station refers to a complete set of equipment used for mass production of asphalt concrete. Asphalt mixing equipment is mainly composed of batching system, drying system, combustion system, hot material lifting, vibrating screen, hot material storage bin, weighing and mixing system, asphalt supply system, powder supply system, dust removal system, finished product bin and control system, etc. It is a necessary equipment for building expressways, municipal roads, airports and ports.

Main Details

Burning System

- 50mm thick insulation layer, small heat loss.

- "Butterfly" elastic connection plate design to avoid elastic cracking -Italian.

- EBICO oil/gas/coal burners: High combustion efficiency, energy saving and low emissions

- Honeywell temperature control system for safe and easy operation.

Drying Drum

1. Siemens motor with hard tooth surface reducer, friction drive type transmission, smooth rotation of the drum.

2. Optimize the design of the board, so that the heat dissipation is uniform, improve the utilization efficiency.

3. 50mm insulation layer and stainless steel surface, reduce heat loss.

Cold Aggregate Feeding Bin

- The silo volume and the number of hoppers can be customized according to user needs.

- The silo adopts split design, which can effectively reduce the transport size and ensure the volume of the hopper.

- The use of seamless annular belt, reliable performance and long service life, belt extraction machine adopts flat belt and baffle design, easy maintenance and replacement.

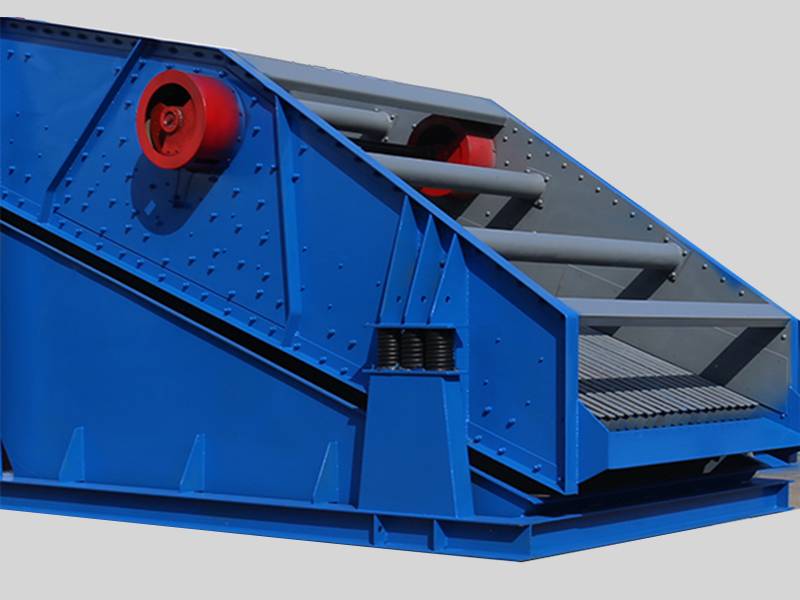

Screening System

- Vibrating screens that apply world famous vibration motors are completely sealed.

- Aggregate storage bin adopts large bin structure to avoid material overflow.

- Aggregate bins are separated by high strength wear-resisting plate to avoid aggregates mixing.

Control System

- Fancy control room for operator, nice operating environment and good sound insulation effect.

- Control room is equipped with split-type air conditioner, aluminium alloy sliding windows, wood floor and so on.

- All operations are integrated in one room, auto and semi-auto control makes it easy to operate.

Advantages

Service

Pre-sale Services

- Quick response.

- Provide detailed quotation.

- Provide scheme design and site planning.

- Accept customer's visit.

On-sale Services

1. If necessary, send technicians to the site for installation and commissioning.

2. Provide complete technical information.

3. Free training of operators.

After-sale Services

- One year warranty for mixing equipment, two years warranty for core electrical appliances, free accessories for quality problems during the warranty period, except for wearing parts.

- Make regular remote visits.

- Lifelong after-sales technical support service.

Customer Visits

Delivery

Application